Equipment

・Electric furnaces (horizontal position: annealing purposes)

(Wound up by all people in the group, 2013)

・Electric furnaces (vertical position: melting purposes)

(Set up by Mr. Horii, a senior student, 2013)

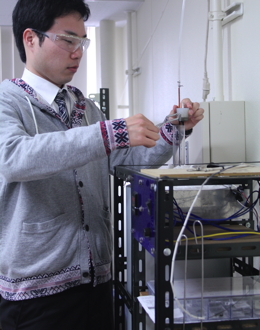

・Vacuum sealing station

(Set up by all people in the group & maintained by Mr. Horii, a senior student, 2013)

・Polisher wheel

(Refurbrished by Mr. Tamaru, a senior student, 2013)

・Hand polishing apparatus

(Designed and assembled by Mr. Tamaru, a senior student, 2013)

・Unidirectional solidification furnace (casting type)

(Set up by Mr. Sudo, a senior student, 2013)

・Unidirectional solidification furnace (Bridgman method)

(Designed and assembled by Mr. Suzuki, a senior student, 2013)

・Differential Scanning Calorimetry (DSC), Diamond DSC, Perkin Elmer

(In operation)

・Optical microscope w/ digital viewing system

・Ball mill system ("Planet Min," Nagao System Inc., 2014)

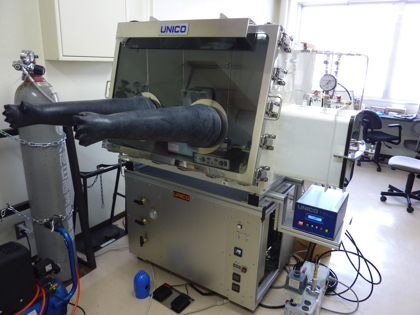

Hybrid heating system with DC pulse plus RF induction

Uniaxual pressure controlled up to 3t